The journey of polyethylene foam (PE foam) is nothing short of fascinating. It began in the early 1950s when scientists stumbled upon a way to create a lightweight, durable material that would revolutionize various industries. Can you imagine a world without this versatile foam? From humble beginnings, PE foam has evolved into a crucial component in packaging and insulation, making it an unsung hero in our daily lives.

Initially, the production of PE foam was a complex process, requiring extensive research and development. However, as technology advanced, manufacturers discovered more efficient methods to produce this material. Today, PE foam is not just about functionality; it embodies innovation and sustainability. With its closed-cell structure, it offers excellent thermal insulation and shock absorption, making it ideal for protecting fragile items during shipping or providing comfort in sports equipment.

As we delve deeper into the applications and future trends of PE foam, it’s essential to appreciate how this material has grown from a mere concept to a vital reality that impacts countless sectors, including construction, automotive, and consumer goods. PE foam is here to stay, continually adapting to meet the demands of an ever-changing world.

History of PE Foam Development

The journey of polyethylene foam began in the early 20th century, when scientists were exploring new materials for various applications. It was in the 1950s that the first commercial production of PE foam took place, marking a significant milestone in materials science. Initially, it was used primarily in packaging and insulation due to its lightweight and durable nature.

As the years progressed, innovations in production techniques revolutionized the way PE foam was manufactured. The introduction of cross-linking technology in the 1970s enhanced its properties, making it even more versatile. This advancement enabled the foam to be used in a wider range of applications, from automotive interiors to sporting goods. The ability to customize the density and thickness of PE foam opened doors to countless possibilities.

Furthermore, the late 20th century saw an increased focus on environmental sustainability. Manufacturers began exploring biodegradable alternatives and recycling methods, reflecting a growing awareness of ecological impacts. Today, the evolution of PE foam continues, driven by technological advancements and the demand for sustainable materials. The history of PE foam is not just about its development; it’s a testament to human ingenuity and the quest for innovation.

Applications of PE Foam

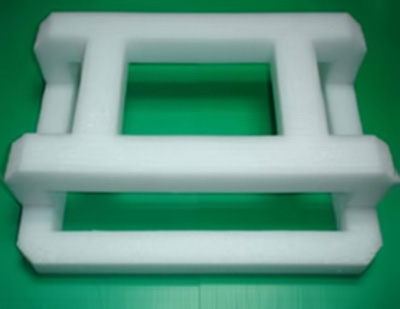

Polyethylene (PE) foam has carved out a significant niche in various industries, thanks to its remarkable properties such as lightweight, durability, and versatility. One of the most prominent applications is in packaging. Imagine receiving a fragile item, like a glass vase, perfectly cushioned in a layer of PE foam. This material absorbs shock and protects products during transport, ensuring they arrive in pristine condition. It’s like wrapping your valuables in a soft, protective embrace!

Beyond packaging, PE foam plays a crucial role in insulation. Its thermal resistance makes it an ideal choice for building materials, helping to maintain energy efficiency in homes and commercial buildings. Picture a cozy room during winter; the walls are insulated with PE foam, keeping the cold at bay and warmth inside. This not only enhances comfort but also contributes to energy savings.

Furthermore, PE foam is widely used in cushioning applications, such as sports equipment and automotive interiors. The foam acts as a shock absorber, providing comfort and safety. For instance, think about the padded seats in your car or the cushioned soles in your running shoes—both utilize PE foam to enhance user experience.

In summary, the applications of PE foam are vast and varied, making it an indispensable material across multiple sectors, from packaging to insulation and cushioning. As technology continues to advance, we can only anticipate even more innovative uses for this fantastic material.

Future Trends in PE Foam Technology

The future of polyethylene (PE) foam technology is brimming with possibilities that could revolutionize its applications and sustainability. As industries increasingly focus on eco-friendly materials, the demand for sustainable PE foam is on the rise. Innovations in production processes are paving the way for biodegradable and recyclable options, making it easier for companies to meet environmental regulations while still benefiting from the unique properties of PE foam.

Moreover, advancements in smart technology are set to transform how PE foam is utilized. Imagine packaging that can monitor temperature and humidity levels! This could drastically enhance the safety and integrity of sensitive products during transit. The integration of sensors within PE foam could lead to significant improvements in logistics, ensuring that goods arrive in perfect condition.

Additionally, research is ongoing to explore new applications for PE foam across various sectors, including healthcare and automotive industries. Its lightweight and cushioning properties make it an ideal candidate for protective gear and components in vehicles. The potential is limitless!

In summary, as we look ahead, the evolution of PE foam technology is not just about enhancing its existing features but also about embracing a more sustainable, smart, and versatile future. Are you ready to see how these trends will unfold?

While coming to the end of our article, do not forget to review the following service pages of Durfoam: